What was this year’s biggest 3D printing news? The 3D Printing Industry Review of the Year is here.

Throughout March, the merger and acquisition saga between Stratasys, Desktop Metal, 3D Systems and Nano Dimension continued to unfold. In response to hostile acquisition efforts by Murchinson Ltd., Nano Dimension launched a speculative $1.1 billion bid for Stratasys. Murchinson and Nano DImension made contradictory statements following a Special General Meeting of Shareholders.

Elsewhere, a number of additive manufacturing developments were made within the automotive sector, whilst research initiatives continued to pick up pace.

Read on for comprehensive news coverage from March 2023 which includes the likes of Nano Dimension, Stratasys, Max Planck, Czinger, Sakuu, and more.

Nano Dimension and Stratasys’ Merger and acquisition saga escalates

Last month, Murchinson, a relatively unknown activist fund, publicly announced plans to acquire Nano Dimension, with hopes to oust the board and spend funds in an alternative manner. In response, Nano Dimension went on the offensive, making a $1.1 billion offer for 3D printer manufacturer Stratasys in March.

Nano Dimensions first showed an interest in Stratasys in July 2022, when it acquired a 12.12% stake in the Rehovot-based company. Stratasys swiftly enacted a poison pill defense to guard against the unwanted hostile takeover, giving investors the right to purchase additional shares in Stratasys for a lower cost than an “acquiring person.” The Rights Plan was set to expire on July 24, 2023.

The offer made by Nano Dimension to acquire Stratasys came to $18.00 per share, or $1.1 billion in cash. At the time, Nano Dimension highlighted that this offer represented a 36% premium on the closing price of Stratasys as of March 1st, 2023.

Later in the month, Stratasys announced that its board had unanimously rejected the Nano Dimension bid. The Stratasys board concluded that Nano’s proposal undervalued the company, and was therefore not in the best interest of its shareholders. In response, Nano Dimension submitted a revised proposal to acquire the remaining Stratasys ordinary shares for $19.55 per share in cash.

Nano Dimension’s feud with Murchinson also continued into March. Following a Special General Meeting of Shareholders, both companies published contradictory statements regarding the meeting’s outcome.

The activist investor asserted that all four of its proposals received overwhelming support, a claim directly disputed by Nano Dimension. Whilst the proposals received at least a 92% share of the votes, Nano argued that the percentage of outstanding Nano ordinary shares present was less than 13%, excluding shares owned by Murchinson and Anson.

As March came to a close, Nano Dimension began legal action against Murchinson, alleging that the activist improperly acquired and misused their shareholding interests in Nano. This marked the beginning of the end for Murchison’s acquisition efforts, which ultimately came to nothing.

However, M&A activity between Stratasys, Nano Dimension, Desktop Metal, and 3D Systems continued into the months ahead.

Research initiatives of the month

On another note, March also focused on advancements in 3D printing research projects. Massachusetts Institute of Technology (MIT) researchers developed a 3D printing method to create flexible, soft replicas of patients’ hearts.

By transforming medical images into a 3D computerized model, the team prints a soft, anatomically correct shell mirroring the patient’s heart. Sleeves, resembling blood pressure cuffs, encase the 3D printed heart and aorta, replicating the heart’s pumping action. This patient-specific approach aims to assist doctors in selecting ideal implants based on both anatomy and function, offering a tailored solution for heart-related treatments.

RWTH Aachen University‘s Digital Additive Production facility (DAP) in Germany explored a zinc-magnesium alloy for lattice structures, addressing limitations in current bone defect treatments as a part of the BioStruct project. Laser Beam Powder Bed Fusion (PBF-LB) is essential for creating these structures, offering new design options for patient-specific implants.

The BioStruct project focuses on bioresorbable implant concepts for patient-friendly bone healing, utilizing algorithmic lattice structure design with ZnMg alloy. These findings were to be expanded in the reACT alliance, aiming to produce customized, bioresorbable implants that meet patient-specific needs and enhance therapy.

Elsewhere, Mexico-based company MANUFACTURA, led “The Eggshell Project” aiming to convert organic waste into sustainable building materials using a KUKA KR-150 robotic arm. The project utilizes 3D printing to create bioceramic blocks from discarded eggshells combined with sustainable aggregates.

This approach addressed the environmental impacts of the ceramics industry and Mexico’s food waste. The resulting sustainable material includes the Eggshell Bricks Wall and Eggshell Column, demonstrating circular processes and emphasizing environmental consciousness and technological advancements.

3D printing speeds up automotive innovation

Driving into the automotive sector, 3D Systems announced BWT Alpine F1‘s purchase of four SLA 750 3D printers for wind tunnel testing. Using Accura Composite PIV material, these machines enhance component production with high sidewall and surface quality, feature detail, and geometric accuracy, reducing preparation time. Having already used 3D Systems’ technology, Alpine F1 found the SLA 750 to provide superior part quality and increased productivity.

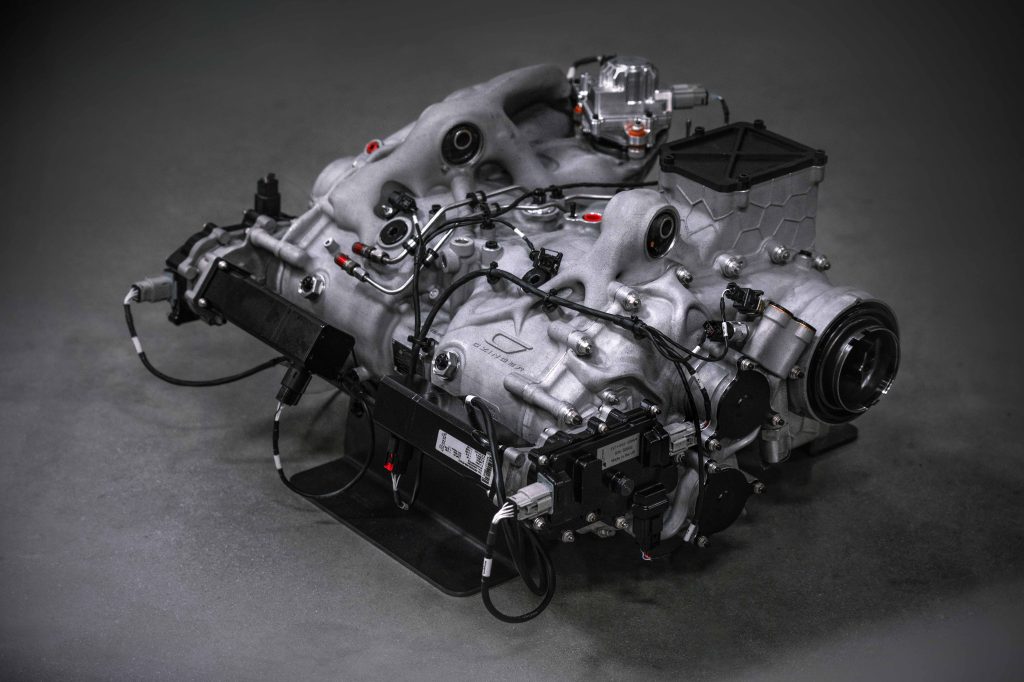

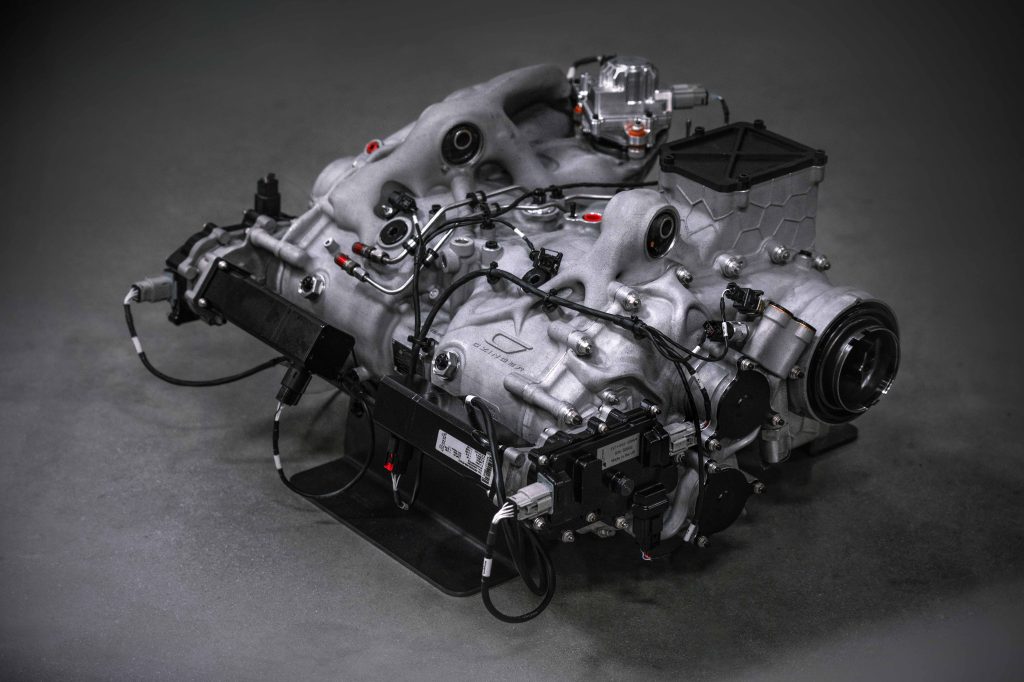

California’s Czinger Vehicles partnered with Xtrac to create an industry-first 3D printed gearbox for the 21C Hypercar. This 7-speed semi-sequential gearbox features sub-100ms shifts, high torque per mass, and a 48V-electrically actuated twin barrel system.

Using a proprietary aluminum in a unique printing process, the gearbox achieves significant weight savings, structural performance, and efficient printing times. This approach eliminates tooling needs, accelerating development and allowing real-time design improvements.

Luxury car customization company ARES Modena partnered with Roboze for industrial 3D printing for the customization of its supercars. ARES used Roboze’s ARGO 500 FFF 3D printer to enhance process repeatability, precision, and custom part production using high-performance polymers.

ARES Modena specializes in bespoke vehicles, such as the Bentley Mulsanne Coupe. Alberto Migliorini, Head of Technologies at ARES Modena, cited Roboze’s industrial approach and materials science knowledge as key factors. The ARGO 500’s large build volume enables the printing of larger parts, and it uses advanced polymers suitable for aerospace, automotive, and medical applications.

Sakuu’s $705M SPAC valuation onboard

In a significant development, Kavian platform manufacturer Sakuu Corporation entered into a definitive business combination agreement with Plum Acquisition Corp. I (Plum), a Special Acquisition Company (SPAC).

After completion, the merged entity will be named Sakuu Holdings Inc. and listed on a US national exchange as ‘SAKU’, with an estimated enterprise value of $705 million. Sakuu specializes in next-gen lithium-metal and all-solid-state batteries, utilizing proprietary multi-material, multi-process AM technologies.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows One of the BWT Alpine F1 Team’s cars in the pits at the Miami Formula 1 GP. Photo via the BWT Alpine F1 Team.