In e-commerce, nothing is more complex than procurement in large organizations acquiring goods and services.

Unlike simple online buying or selling through websites or marketplaces, corporate procurement involves many extra steps that must be tightly controlled, including evaluating suppliers, running auctions or tenders, managing contracts, and analyzing company-wide spending.

Of course, many companies use digital technologies to some extent to support their procurement processes.

However, industry studies show that lots of organizations are still in the early-mid stages of transformation, where teams still largely rely on disparate systems, manual request approvals, and disconnected supplier data, which slows down decision-making and multiplies risks.

In this guide, we explore what digital procurement really means, why it matters for modern enterprises, which components define a successful transformation, how to implement it step by step, and what challenges organizations should be prepared to overcome.

What Is Digital Procurement?

Digital procurement refers to the use of digital technologies to automate, integrate, and optimize procurement processes within sourcing, purchasing, supplier management, and spend analysis.

It replaces paper-based work cycles, disconnected tools, and manual approvals with centralized platforms, live data, and automated support.

However, it is important to clarify that digitalization is not about collecting applications or implementing software systems for their own sake.

It’s about using tech to free procurement specialists, so that they can focus on areas where human judgment still remains essential: understanding the nuances of the supplier market, analyzing the scope of projects, advising on risks, and coordinating supplier-related decisions.

Why Digital Procurement Matters

Research highlights that, despite the fact that actual digital maturity (where technology is implanted deeply into processes) is far from complete, procurement organizations expect to reach a 70% rate of digitalization by 2027, indicating strong intent.

In fact, you don’t need to dig deep to see the advantages of technology. The impact of digital procurement is most evident in better efficiency and cost control.

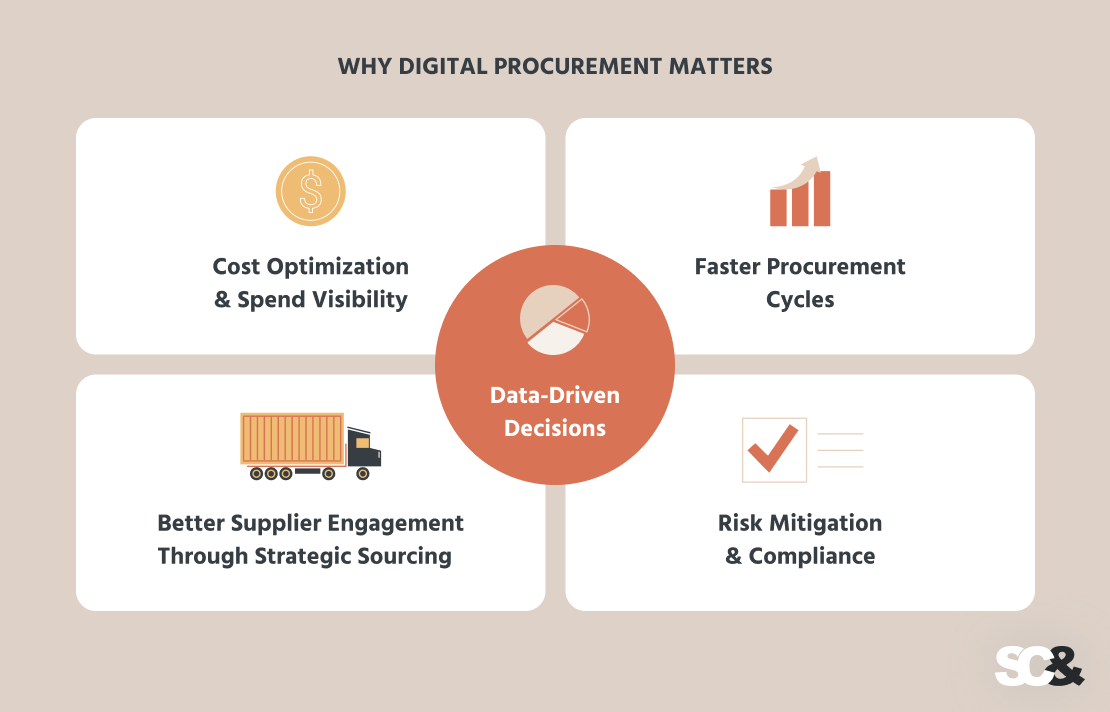

Why Digital Procurement Matters: Key Business Benefits

- Cost Optimization and Spend Visibility: Cost optimization and full spend visibility are among the most direct benefits. E-procurement platforms bring spend data from suppliers, categories, business units, and regions into a single view, helping detect off-contract spending, adjust supplier agreements, and measure achieved savings.

- Faster Procurement Cycles: Another major advantage is that procurement sequences can be performed at a much quicker pace. Automation replaces manual steps and fragmented approvals, supporting faster processing of requests, quicker supplier responses, and better matching with business needs.

- Better Supplier Engagement Through Strategic Sourcing: Digital procurement also strengthens supplier engagement. Centralized portals create a single standard for registration, document exchange, performance tracking, and communication. This way, suppliers get a clearer sense of expectations, deadlines, and compliance requirements.

- Risk Mitigation and Compliance: Equally important is risk mitigation and regulatory adherence. Digital systems help track contracts, certifications, service-level agreements, and regulatory requirements across the supplier base, as well as flag contract expirations, gaps, or performance problems before they escalate into severe risks.

- Data-Driven Decisions: Lastly, digital tools help procurement teams use data, not guesswork, to make decisions. Analytics transform raw data into insights that guide strategy and daily operations.

Components of Successful Digital Procurement Transformation

According to Statista, the time, effort, and resources a company already spends on procurement get better results when the process is digitalized. But what exactly constitutes successful digitalization?

Strategic Objectives

Digital procurement should always begin with explicit goals. Technology is a tool to achieve business outcomes, not the other way around. Companies need to decide what they want to improve — be it cutting costs, reducing risks, speeding up procurement cycles, or strengthening supplier partnerships.

For example, a company with high maverick spend might focus on centralizing purchases, while another struggling with supplier delays might aim to speed up approvals.

At the same time, strategic priorities often depend on the industry. Healthcare procurement transformation usually focuses on strict compliance and supplier documentation control.

Telecom procurement transformation and high tech procurement transformation are typically driven by the need for faster sourcing. In manufacturing, OEM procurement transformation is often centered around supply chain stability, delivery timelines, and avoiding production disruptions.

Overall, knowing your gaps and goals first helps direct which tools and processes to cover.

A Clear Procurement Transformation Roadmap

Don’t try to digitalize everything at once; it can be confusing and definitely expensive. Research shows that large technology projects often harshly exceed their budgets or timelines when approached as one large action.

In a study of 1,471 IT projects, the average cost overrun was around 27%, and about one in six experienced extreme overruns (≈200%+).

Instead, it’s important to create a roadmap that embraces the most valuable processes first. For example, start with automating purchase orders or invoice approvals to see quick results.

Early wins show the benefits to executives and stakeholders, making it easier to expand digitalization to more complex areas later, such as contract management or supplier risk analysis.

Change Management and Training

Digital procurement often implies new ways of working. Teams need training, guidance, and leadership support to use the tools to their maximum.

For example, if managers get a report on supplier performance but aren’t trained to understand it, the tool won’t help them make better decisions. Supporting teams through the change guarantees the technology actually brings value.

Standardized Processes Before Automating

Automation speeds up processes, but it can also amplify inefficiencies. Before introducing technology, make sure workflows are systematized and coordinated.

For example, if different departments use different approval paths for purchase requests, automating these workflows without standardization could create disorder and errors.

Governance and Track Metrics

Clear ownership and measurable KPIs are important to long-term success. Companies need to know who is responsible for what and track performance to ensure the new processes are working.

Useful metrics include how long purchase orders take, how much spend is off-contract, supplier performance, and cost savings achieved through digital initiatives. Watching these indicators helps determine problems and improve procurement.

| Component | What It Means | Example |

| Strategic Objectives | Set clear business goals before choosing tools. | Reduce maverick spend, speed up approvals, improve compliance. |

| Transformation Roadmap | Digitalize step by step, starting with high-impact areas. | Automate purchase orders first, then contracts and supplier risk. |

| Change Management | Train teams and support adoption. | Users learn how to work with dashboards and new workflows. |

| Process Standardization | Fix and align workflows before automating them. | Unify approval rules across departments. |

| Governance & KPIs | Assign ownership and track measurable results. | Monitor cycle time, savings, compliance, supplier performance. |

Key Components of Successful Digital Procurement Transformation

Implementing Digital Procurement: A Step-by-Step Guide

Any initiative involving organizational change can seem like a daunting task, but it doesn’t have to be. By developing a step-by-step plan, you can prepare for any unexpected obstacles.

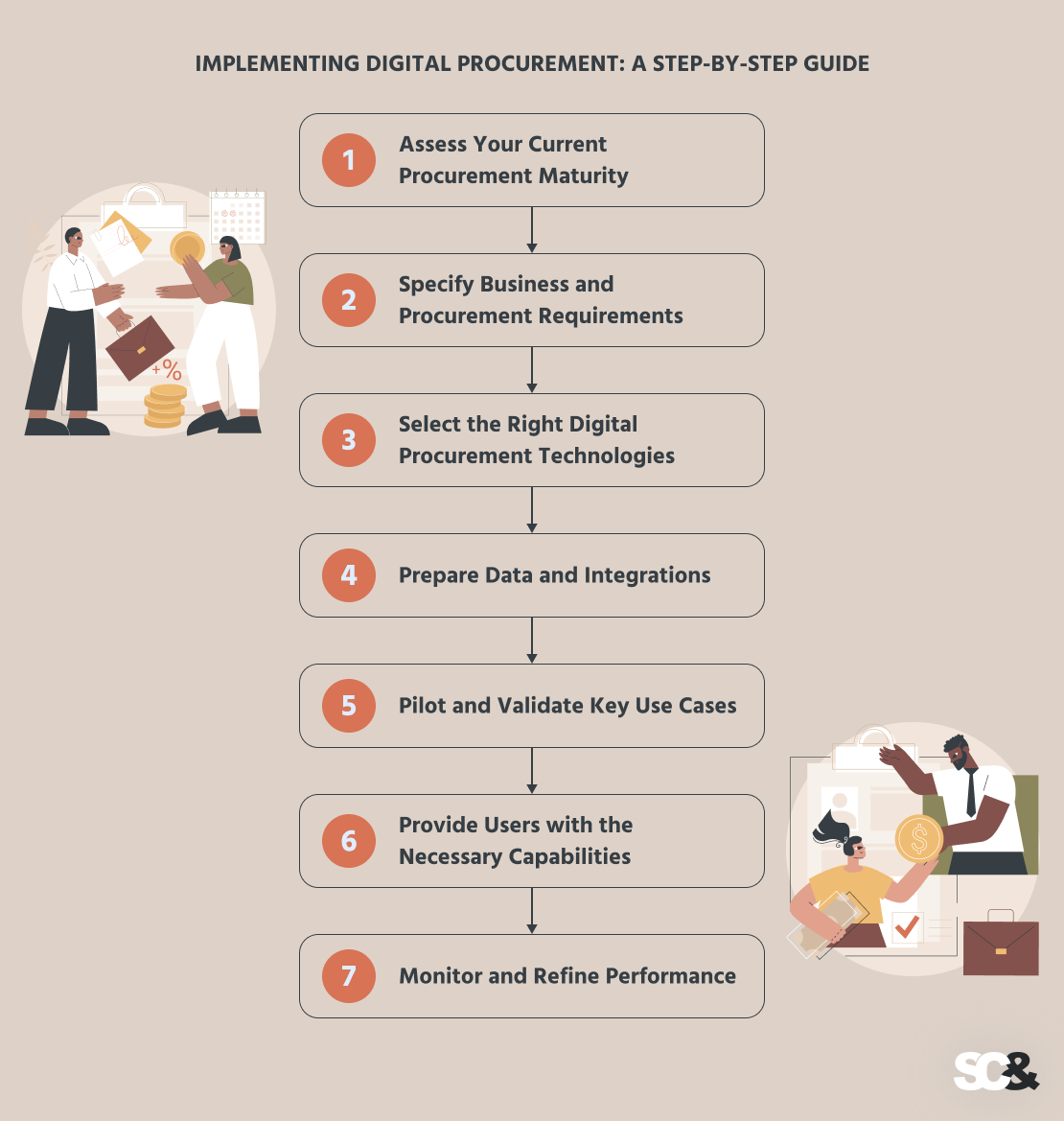

Digital Procurement Implementation Roadmap (7 Key Steps)

Step 1: Assess Your Current Procurement Maturity

Before you invest in new technology, it’s important to understand where you are today.

Many companies (though far from true maturity) aren’t starting from zero — basic digital tools like e-procurement or spend analytics may already be in place.

A structured assessment can reveal important gaps, for instance, a company might already have an e-procurement system but still depend on manual approvals, or have good spend data but no analytics tools to make sense of it.

Without a clear picture of your current maturity:

- You might implement technology that doesn’t solve your real problems.

- You risk repeating manual work in a new system.

- You may undervalue training needs or integration complexity.

Step 2: Specify Business and Procurement Requirements

After you understand the current state of your procurement function, the next step is to turn business objectives into tangible procurement requirements. Saying “we need faster cycle times” is too vague. What does faster really mean for your organization? What specific results are you expecting?

The goal here is to turn broad business outcomes into clear, measurable conditions that technology and process changes must support. A specifically defined goal might look like this: “Approvals must be completed within 24 hours and automatically routed based on spend level.”

Step 3: Select the Right Digital Procurement Technologies

Choosing digital procurement technologies should start with business reality, not vendor promises or trend-driven decisions.

Before looking at specific tools, a company needs a clear understanding of its procurement complexity, transaction volumes, regulatory requirements, and how procurement fits into the broader enterprise framework.

One of the first decisions is whether to rely on a single end-to-end procurement platform or a combination of specialized tools.

Multiple specialized tools offer functionality in specific areas, such as sourcing, supplier risk management, or advanced spend analytics, but it also increases integration complexity and places higher demands on data governance and IT support.

Unified platforms typically cover the entire source-to-pay cycle, offering centralized data and simpler governance. They are often a better fit for organizations seeking faster implementation, predictable costs, and easier user adoption.

However, such platforms can be limiting for companies with complex procurement models, industry-specific requirements, or advanced analytics needs, where certain modules may lack depth.

In practice, many enterprises adopt a hybrid approach, using a core procurement platform as a foundation and extending it with specialized tools where differentiation matters most.

Another choice is between market-ready solutions and custom-made procurement systems. Off-the-shelf platforms provide proven functionality, faster deployment, and regular vendor updates, making them suitable for organizations with standard procurement processes or limited internal development capacity.

Custom solutions, such as those made by SCAND, on the other hand, are justified when procurement processes are deeply tied to unusual business models, strict compliance requirements, or legacy environments that standard platforms cannot support.

Custom development allows organizations to arrange work sequences, data models, and integrations precisely around their needs, but it requires higher upfront investment, longer implementation timelines, and regular maintenance.

Step 4: Prepare Data and Integrations

Digital procurement only works well when the data is accurate and systems properly connect.

Even the best procurement management platform will not yield results if supplier information is outdated, product categories are inconsistent, and spending data is scattered across different tools and spreadsheets.

For example, one department may list a supplier as “IBM,” while another uses “IBM Corp.” If the data isn’t cleaned, it becomes difficult to see total spending or track supplier performance correctly.

As for integrations, they should be planned from the very beginning. Procurement does not work separately from the rest of the business.

In most cases, procurement tools should integrate with:

- ERP systems (budgets, master data, purchase orders)

- Finance systems (invoices, payments, approvals)

- Inventory tools (stock levels, reorders)

- Supply chain systems (delivery tracking, supplier performance)

- PIM systems (centralized product information, attributes, and catalog management)

Without integration, teams may still have to enter the same data manually, leading to delays and the risk of errors.

Step 5: Pilot and Validate Key Use Cases

Instead of launching the entire digital procurement system at once, companies should begin with a few pilot projects.

A pilot is a controlled rollout focused on one or two processes that can produce quick results. Typical pilot areas include purchase approvals, spend tracking, supplier onboarding, or invoice matching.

Starting small allows teams to test how the solution works in real conditions, confirm whether it has value, and fix problems without disrupting the whole organization.

For example, a company might first automate purchase requests for one department. If it reduces approval time and improves control, the same approach can then be expanded across the business.

Pilots also make it easier to prove ROI and get buy-in from stakeholders before investing in a full rollout.

Step 6: Provide Users with the Necessary Capabilities

Even the best procurement platform is useless if employees don’t use it. That’s why adoption is one of the most important parts of digital transformation.

Companies need to provide training, clear instructions, and support. Employees should understand not only how the system works, but also why it matters and how it helps them do their job faster and with fewer mistakes.

For example, if managers see that approvals take less time and require fewer emails, they are much more likely to support the new process instead of avoiding it.

Step 7: Monitor and Refine Performance

The digitalization of procurement is not a one-time project. After implementation, companies must track the results and improve the process over time.

This means monitoring key performance indicators such as request approval speed, procurement cycle time, compliance levels, cost savings, and supplier performance. Regular reviews help identify what is working well and where delays or inefficiencies still exist.

Challenges and Barriers to Successful Transformation

Digital procurement transformation can fail even when companies invest in good platforms and modern tools. The most common problems are not technical; they are strategic and administrative. Below are the main pitfalls enterprises should be aware of.

- Buying technology before recognizing problems. When organizations purchase a platform without clear use cases, the result is often expensive “shelfware” that teams don’t use. This also creates frustration and resistance, because employees feel forced to adopt tools that don’t solve their day-to-day issues.

- Following a one-size-fits-all course. Not every activity should be automated to the same degree. Approvals, invoice matching, or catalog purchases can be automated almost fully. However, strategic sourcing, supplier negotiations, and risk management often require expert involvement and strong relationships. Successful transformation means understanding which processes should be digital-first and which should remain human-led.

- Set-and-forget mindset. Procurement management tools require monitoring, updates, and optimization. Without proper management, workflows become outdated, integrations break down, and user adoption declines. Over time, companies may find themselves paying for platforms that no longer provide tangible benefits.

SCAND’s Expertise in Digital Procurement Transformation

At SCAND, we blend extensive experience in software development with a practical understanding of business processes to help organizations turn their procurement processes to data-driven systems.

With over 25 years in custom software development, we have supported hundreds of companies in many industries (logistics, manufacturing, retail, enterprise services, etc.) in creating custom digital solutions that solve real business problems and improve performance.

Our approach to the digital transformation of procurement processes is based on prioritizing strategy first, and then technology. We work with clients to assess the current maturity level of their processes, clarify requirements, and define criteria for success.

From there, we design and build systems that automate key procurement workflows, connect with other systems, and provide actionable insights through reporting and analytics.

A strong example of our procurement capabilities is the Procurement Management System we developed for a customer seeking to automate and modernize their purchasing processes.

In this project, SCAND built a web-based procurement system that centralized spend and supplier data, offered live reporting and analytics, and streamlined key tasks such as:

- Tracking suppliers and customers across the supply chain

- Managing purchase orders and contracts

- Coordinating logistics and document workflows

- Providing dashboards that give visibility into expenses and procurement performance.

Conclusion

Digital procurement transformation is no longer optional for enterprises that want to keep up with the rest of the market. By moving from manual/half-digital, fragmented processes to integrated, data-backed workflows, organizations can reduce costs, improve supplier collaboration, and speed up procurement cycles.

But success requires more than just technology. It depends on clear goals, standardized processes, careful data preparation, phased rollout, and strong user adoption.

Companies that follow a structured, phased approach can reduce risks, maximize return on investment, and create a procurement function that not only supports day-to-day operations but also contributes to achieving business goals.