News briefs for the week take a look at breaking news from logistics leaders in U.S., with Symbotic and SoftBank partnering to create a WaaS called GreenBox, with SoftBank additionally launching its Project R, and Amazon launching its Sequoia robot/AI overhaul in Houston, then it’s grippers evolving into hands for industrial robots and cobots, and finally, the first-ever connecting of a robotic prosthetic hand directly to the brain.

Finally, tech help for SME warehouses

U.S.-based Symbotic and Tokyo-based SoftBank are joining forces to create low-cost, AI-based logistics automation services for small-to-medium (SME) warehouses, which the pair say is a $500 billion industry. The joint business is called GreenBox Systems LLC and was initially capitalized 65% by Softbank and 35% by Symbotic, for a total of $100 million.

According to the U.S. Bureau of Labor Statistics, there are “over 21,000 warehouse establishments in the US (as of 2023).” 80% of which have ZERO automation. With nearly 15,000 of those warehouses in the SME category and unable to pay the reported $25 million it takes to automate, GreenBox will offer a warehouse as a service model (WaaS).

According to the U.S. Bureau of Labor Statistics, there are “over 21,000 warehouse establishments in the US (as of 2023).” 80% of which have ZERO automation. With nearly 15,000 of those warehouses in the SME category and unable to pay the reported $25 million it takes to automate, GreenBox will offer a warehouse as a service model (WaaS).

Symbotic, which already generated “market heat selling AI-powered robotic warehouse management systems” to mega-size clients, including Walmart, Target, and Albertson’s, will now offer a WaaS monthly service to warehouses that “don’t have the money to buy them outright.”

“I’ve seen a lot of robotics tech and I’ve never seen anything like it in my life,” TD Cowen analyst Joseph Giordano said. “Compared to what it replaces, it’s like day and night.”

“GreenBox taps into the powerful potential of AI and other enabling technologies in supply chains, while also making the benefits of automation accessible to more businesses through an ‘as-a-service’ offering,” SoftBank’s Vikas Parekh said in a release.

“In partnership with Symbotic, GreenBox will equip customers with more intelligent, streamlined, and scalable warehousing solutions while eliminating the burden of major capital expenditures.”

Tech watch: SoftBank’s secret “Project R”

Looks like the $100 million Symbotic-SoftBank hookup as GreenBox Systems may well be just the beginning of a new run at acquiring more emerging technologies. What SoftBank calls “Project R”.

Project R is a tightly-held secret venture, but SoftBank Chairman Masayoshi Son, according to recent leaked reports, “has met with several high-profile investors and entrepreneurs to discuss potential investments in areas such as artificial intelligence, robotics, and autonomous vehicles.”

Project R is a tightly-held secret venture, but SoftBank Chairman Masayoshi Son, according to recent leaked reports, “has met with several high-profile investors and entrepreneurs to discuss potential investments in areas such as artificial intelligence, robotics, and autonomous vehicles.”

Whatever the final investments, look to AI to be the driver. Son-san said he believes artificial intelligence will surpass human intelligence within a decade, and the companies and people that work with AI will be the leaders in the next 10 to 20 years.

As for logistics, SoftBank already has investments in Boston Dynamics, AutoStore, Berkshire Grey (acquired in 2023), in addition to its recent joint ‘Warehouse as a Service’ (WaaS) venture with Symbotic, called GreenBox Systems (see above).

“Project R is seen as a way for SoftBank to diversify its investment portfolio and to place new bets on emerging technologies. The company has been facing increasing scrutiny in recent years over its investments in the Vision Fund, which has lost billions of dollars.”

Amazon overhauls with new robotics & AI: Sequoia

Amazon announced a new logistics overhaul for its operations using advanced robotics and AI that it calls Sequoia (reference to giant, ancient trees). Amazon launched the system this week at one of its warehouses in Houston.

Amazon announced a new logistics overhaul for its operations using advanced robotics and AI that it calls Sequoia (reference to giant, ancient trees). Amazon launched the system this week at one of its warehouses in Houston.

Sequoia, said David Guerin, the company’s director of robotic storage technology, helps to put items for sale online much faster and makes it easier to predict delivery estimates. The new program reduces the time it takes to fulfill an order by up to 25%, added Guerin, and can identify and store inventory up to 75% faster.

“The faster we can process inventory, the greater the probability that we’re going to be able to deliver when we said we could,” Guerin said. He expects the new system to make up a significant portion of the company’s operations in the next three to five years.

Faced with increased competition, Amazon has worked to become faster at delivering its products. The company previously transformed its operations to a regionally focused model meant to store items closer to customers. Executives see a connection between delivery speeds and growth.

From grippers to hands for industrial robots

Hands for humanoids? Sophisticated hand technology designed for medical prosthetics could end up on industrial robots and cobots in factories and warehouses…and very probably as all-purpose hands for humanoid robots.

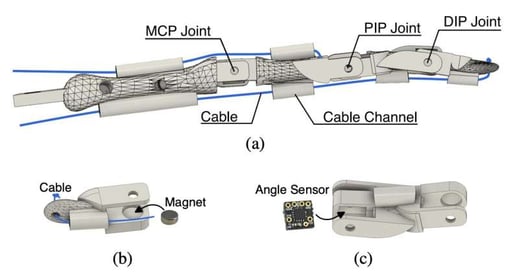

At MIT, in what is being called “increasingly sophisticated robotic systems designed to mimic both the structure and function of the human body,” a robot hand has been developed that could well serve both a medical and industrial function.

At MIT, in what is being called “increasingly sophisticated robotic systems designed to mimic both the structure and function of the human body,” a robot hand has been developed that could well serve both a medical and industrial function.

Robot hands for medical purposes are expensive to build and difficult to scale into mass production, therefore making them ill-suited as grippers for industrial robotics. Until now.

“Researchers at Massachusetts Institute of Technology (MIT) recently created a new highly precise robotic hand that could be easier to upscale, as its components can be crafted using commonly employed techniques, such as 3D printing and laser cutting.”

“This work presents a hybrid bio-inspired robotic hand that combines soft materials and rigid elements,” wrote Chao Liu, Andrea Moncada and their colleagues. “Sensing is integrated into the rigid bodies resulting in a simple way for pose estimation with high sensitivity.”

Eventually, say the researchers, their new design could be integrated with other robotic limbs to create scalable humanoid robots that are better at manipulating objects.

Introduced in a paper A Modular Bio-inspired Robotic Hand with High Sensitivity published in the journal IEEE International Conference on Soft Robotics (RoboSoft, 2023), the MIT hand is based on a so-called modular structure, meaning that it comprises multiple building blocks that can be rearranged to achieve different movements (see video).

Real “mind control” for robot hand

In a first-ever for medical prosthetic hardware, a robot hand has been made to connect directly with the brain and integrate with the nervous and skeletal systems…giving real control and real physical sensations to the recipient.

Previously, the prevailing technique for a robot limb was myoelectric, which is a motor and battery on board the robot hand that reacts to electrical signals through sensors on the exterior skin that are generated by muscles in the residual limb.

Previously, the prevailing technique for a robot limb was myoelectric, which is a motor and battery on board the robot hand that reacts to electrical signals through sensors on the exterior skin that are generated by muscles in the residual limb.

However, “myoelectric signals recorded by surface electrodes are prone to disturbance and interference, thus rendering prosthetic control in daily life unreliable,” say researchers.

Osseointegration, on the other hand, is the process that connects bones to the electrodes implanted in the nerves and muscles. For Karin, her first operation in 2018 attached an MIA Hand from Italy-based Prensilia, which now, five years on, a joint medical team has further endowed with 80% of her former hand control and sensation.

The surgery, called “targeted muscle reinnervation” re-arranges nerves and muscles in the residual limb and links them to the remaining muscles. This allows the brain to send signals to the prosthesis through the nerves, just like it would do with a natural limb (see video).

To develop Karin’s new bionic limb, “a multidisciplinary group of engineers and surgeons from Sweden, Australia and Italy created what they’re calling a revolution for those suffering limb loss, fusing surgery, implants and AI.”

Rickard Brånemark, an MIT researcher on the project says: “By combining osseointegration with reconstructive surgery, implanted electrodes, and AI, we can restore human function in an unprecedented way.”

For the over 50 million limb amputees worldwide, that news is something to smile about. And for millions more, here’s proof that robotics can create new jobs!

![]()