Australian large-format Wire Arc Additive Manufacturing (WAAM) specialist AML3D has reported a second successive quarter of record quarterly cash receipts, reflecting the strength of its US ‘Scale Up’ strategy.

In its Quarterly Activities Report and Appendix 4C for the quarter ended 31 December 2023 (Q2 2024), the company announced cash receipts of AUD $2.46 million. This represents a 4.6% increase compared to $2.36 million reported in the previous quarter.

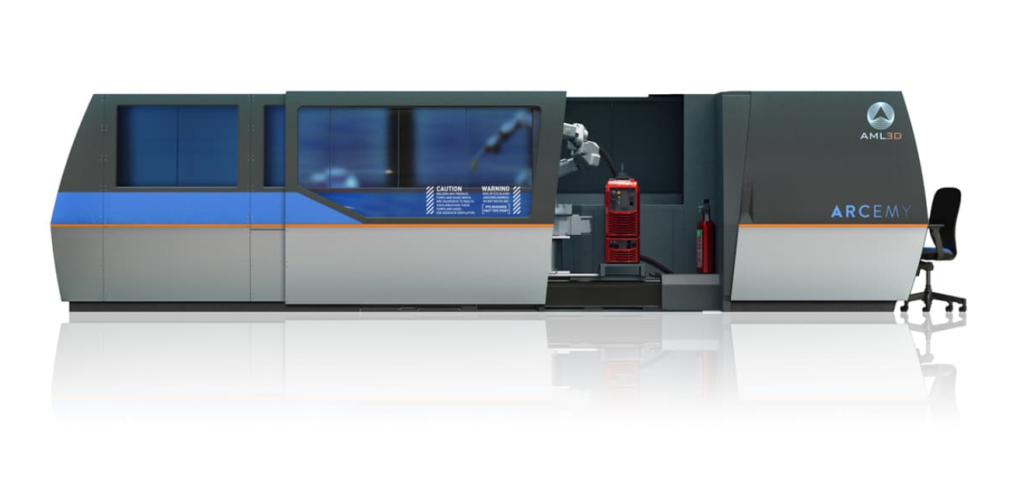

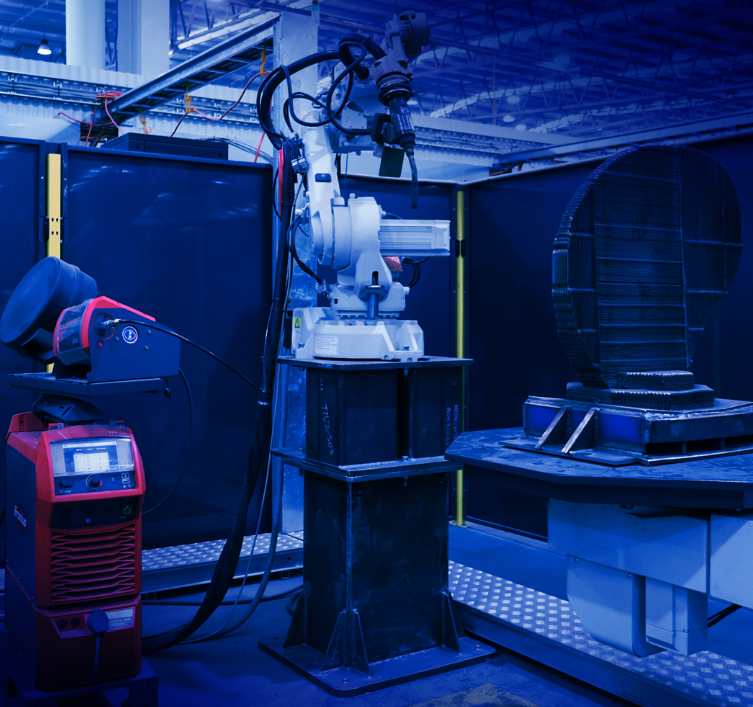

Through its US ‘Scale Up’ strategy, AML3D seeks to secure contracts to address supply chain challenges within the US Department of Defense (DoD), especially the US Navy’s submarine industrial base. The company hopes to become a point of need, additive manufacturing solution through its proprietary ARCEMY advanced WAAM metal 3D printing technology.

According to AML3D, this ‘Scale Up’ strategy delivered over $12 million worth of orders in 2023. Substantial customer receipts have resulted in negligible operating cash flow of $47,000 during Q2 2024, with financial year-to-date customer receipts coming to $4.83 million. Cash on hand at the end of the quarter was $4.2 million, with an outstanding order book of approximately $6.5 million.

AML3D also noted that its US sales pipeline remains robust, with existing defense and Global Tier 1 customers in Australia continuing to expand. This gives the company “confidence of delivering a record revenue performance in FY2024.”

AML3D US ‘Scale Up’ strategy drives orders in Q2 2024

AML3D’s US ‘Scale Up’ strategy has seen the company supply its ARCEMY WAAM technology to support the US Department of Defense’s submarine industrial base and other defense corporations through a number of contracts in Q2 2024.

In November, the company received orders worth close to $5 million for its ARCEMY systems from US Defense contractors Cogitic Corporation and Austal USA. Cogitic’s $2.5 million order will see the defense contractor supply ARCEMY metal 3D printed parts to the US Navy submarine industrial base. Austel USA’s order, worth $2.2 million, saw the company install an ARCEMY WAAM 3D printer at its Virginia-based Advanced Manufacturing Centre.

These deals followed the installation of large scale ARCEMY X-Edition 6700 3D printers to support the US Navy’s submarine program at the Oak Ridge National Laboratory in Tennessee, and the US Navy’s Center of Excellence in Danville, Virginia. Elsewhere, AML3D delivered the inaugural order of an ARCEMY 2600 3D printer for US Navy submarine component partner Laser Welding Solutions.

In addition to the delivery of ARCEMY 3D printing hardware, AML3D has also delivered component and alloy testing programs to meet demand within the US Navy’s industrial base. The company has commenced component and testing contracts for Copper-Nickel and Nickel-Aluminium-Bronze ARCEMY alloys for the US Navy.

Looking to the future, AML3D plans to expand testing into four additional alloys as momentum for its US ‘Scale Up’ strategy builds. The company hopes to secure contracts from additional branches of the US DoD, with a specific focus on defense aerospace.

Away from the US DoD, AML3D’s ‘Scale Up’ also seeks to meet demand within US-based Tier 1 oil & gas and aerospace, including existing clients Chevron and Boeing. For instance, Cogitic Corporation is a key supplier to the civilian oil & gas sector.

AML3D expands global reach

Alongside its US-centered ‘Scale Up’ strategy, AML3D is also working to expand relationships with clients around the world.

Q2 2024 saw the company sign a new prototype part contract with BAE Systems Maritime Australia to support its Hunter class frigate program. AML3D had previously completed feasibility and commercial validation testing programs to demonstrate its 3D metal printers as a cost-effective advanced manufacturing solution that meets the Royal Australian Navy’s standards.

The quarter also saw AML3D secure an Indian process patent for its proprietary Wire Additive Manufacturing (WAM) technology. This follows the company’s long-term investment into securing its intellectual property (IP) globally, which has seen it secure similar patents in the EU, Australia, and Japan.

Additive Manufacturing bolsters US defense capabilities

Metal 3D printing is a growing technology within the US defense industry. In December 2023, Industrial 3D printing materials manufacturer 6K Additive was awarded a $23.4 million grant from the US DoD to secure supply chains and expand its metal upcycling capabilities.

Through this funding, 6K Additive expects to double capacity and expand its domestic upcycling capabilities to create, maintain, protect, and restore US military industrial base capabilities. 6K’s upcycling process leverages a range of waste products including end of life components, machine shop swarf, and scrap from manufacturing processes such as forging and casting.

Elsewhere, US based government and commercial services contractor Amentum is delivering on a $4.6 billion indefinite-delivery/indefinite-quantity (IDIQ) for the US Air Force (USAF) Security Assistance and Cooperation Directorate. This contract sees the company deliver “commercial buying solutions” for Foreign Military Sales (FMS) customers.

As part of this agreement, Amentum is leveraging its 3D scanning and additive manufacturing systems, as well as other technologies such as reverse engineering, robotic process automation (RPA) and other automated best-value decision tools.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a typical ARCEMY metal 3D printing system. Photo via AML3D.